- Sale

- Wheels

- Air Filters

- Brakes

- Exterior

- Engine

- Exhausts

- Suspension

- Gallery

- Information

- Technical

- Alloy Wheel installation

- Avoiding pot holes

- Bedding in tyres

- Correct tyre inflation

- Performance benefits

- Porsche N rated tyres

- Mercedes MO rated tyres

- Quality of a wheel

- Reading your tyre markings

- Selecting the right tyre

- The age of your tyres

- Tyre labelling

- Tyre pressure monitors (TPMS)

- Tyre rotation instructions

- Tyre tread patterns

- What are alloy wheels

- Wheel alignment

- Wheel nut/bolt torque

- Why install larger wheels

- Winter tyres

- Blog

- Services

- Contact

Alloy Wheel Installation instructions

Thank you for purchasing your new alloy wheels from the UK’s ultimate modifying destination.

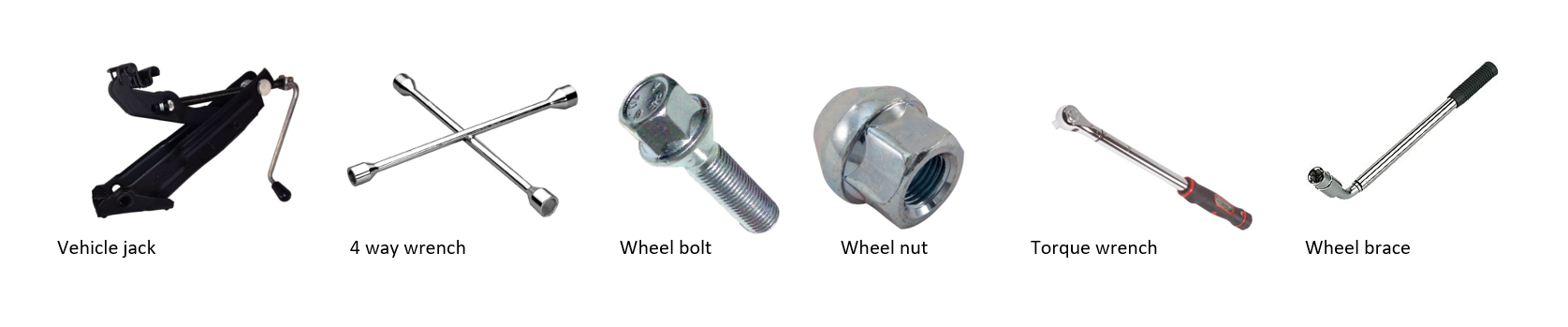

Required items: Vehicle jack, 4 way wrench, Wheel bolt, Wheel nut, Torque wrench, Wheel brace (see below)

Step 1

Best place to find the correct procedure for wheel and tyre removal is in the owner’s manual for your vehicle. To install your new wheels you will need to raise your vehicle slightly, supporting it with a jack and axel stands if available. Be sure to rest the stand of a flat surface.

Step 2:

Carefully remove your standard nuts or bolts with a wheel brace such as the one supplied with your jack in the boot area, a four wheel brace or a socket on a breaker bar. Be wary if using an air gun unless fully trained, this may damage the threads if used incorrectly.

Attention: Check the condition of the vehicles nuts/bolts as you loosen them. If you feel any resistance or see any roughness after removing the wheels, correct it before reinstalling the wheels. Wheels must fit flat against the vehicle’s hubs.

Step 3:

Remove any temporary or loose retaining devices like stud clips or damaged shims if they interfere with the flush fitment of your wheels against the brakes hubs* (*See NOTES below). Hyundai discs may be an exception as these have large bolts holding the discs to the hubs. If aftermarket wheels have previously been used on the vehicle, verify that the previous wheel hubs centring rings (spigot rings) have been removed from the hubs. If you have any questions, please contact of our sales representatives.

Step 4:

In order to verify that you have matching nut/bolt thread sizes, first install the nuts of bolts without the wheel. Next check the fit of the wheel onto the hub of the vehicle. (Some wheel applications may require the use of a centring/spigot ring supplied with your wheels) to create the proper fit onto the hub. The bolt circle of the wheel must match that of your vehicle and the wheel must make full contact to the mating surface of the hub. In some cases you may have decided with our salesperson that you are going to use a ‘vari-bolt’ fitting kit to self locate the nuts/bolts into the hub if not a direct fit.

If the wheel does not match up to the bolt circle of the vehicle, or the wheel does not have full contact to the mounting surface, please contact us immediately on 01727 790 100.

NOTE: We highly recommend applying a coating of copper grease around the hubs to help prevent rust and make easier removal when it’s time to fit new tyres.

Step 5

Place the wheel onto the hub and slowly tighten down to verify brake disc clearance. Check clearances between all parts of the brakes, front and rear, callipers and drums, while offering the wheel up to the hub. Start threading the nuts/bolts with your fingers and tighten them. If you feel resistance while doing this, inspect the stud and nut (or hub and bolt) to see if the threads are clean or obstructed. If the nut/bolt appears obstructed or does not match the thread pitch of your hubs, try another one. If another nut/bolt doesn’t thread any better give us a call. NOTE: Do not force your nuts or bolts on with a wrench. They should be able to be turned by hand. If they can’t, something is wrong! Please call our sales department on 01727 790 100. Only after the nuts/bolts have been installed by hand until finger tight should you tighten them down with your wrench or socket.

Step 6

Put your vehicle’s transmission into neutral and turn each wheel by hand while making certain that the outer edge of the brake disc calliper doesn’t touch the inside of the rim or that the side of the calliper doesn’t come into contact with the backside of the wheel, or the wheel balancing weights. Check for any noises while turning the wheel. Mercedes are critical for bolt length and if any clicking noises are heard please contact us straight away.

If you have any concerns, CALL US! We will be happy to use our experience to help solve your problem. However, if everything is fitting correctly, it’s time to torque them down.

IMPORTANT!

Proper installation requires that the wheel nuts or bolts to be set to the recommended specification for your vehicle. These torque specifications can be found in your vehicle’s owner’s manual. Finish tightening them down with a torque wrench. Use a crisscross sequence tightening opposite nuts/bolts until they have reached their proper torque value. Be careful because if you over torque a wheel you can strip a thread, stretch or break a wheel stud, wheel bolt and cause the wheel, brake disc and/or brake drum to distort.

NOTE: When installing new wheels you should re-torque the nuts/bolts after travelling the first 50 to 100 miles. This is necessary because as the wheels are ‘breaking in’ they may compress slightly allowing their nuts/bolts to lose some of their torque. Simply repeat the same torque procedure listed above.

NOTE: Some brake discs have retaining screws that are not flush with the surface of the disc. Retaining screws are put in place on the assembly line when the vehicle is being manufactured, and serve no further purpose after the vehicle is assembled. Please ensure, if your vehicle does have a protruding retaining screw, it is necessary to remove it before the wheels are installed, as this may fail on the wheels

NOTE:New tyres have a ‘sheen’ across the surface to preserve the material characteristics while in storage. For this reason you should take care while driving the first 20-40 miles (depending on driving style) as the grip levels are not yet at their optimum. They should not be slippery but certainly not at their peak performance.

P.S. May we thank you once again for shopping with RTECSHOP.com, and look forward to being of service to you in the future. If there is anything else we can do for you, please do not hesitate to give us a call. Please keep your receipt for your proof of purchase and please read our terms & conditions of sale on the back of your invoice.